Introduction to Bus Duct Systems

Bus duct systems are prefabricated electrical distribution systems used to efficiently and safely transmit power within a facility. They offer an alternative to traditional cabling methods, providing a more compact, flexible, and reliable solution for power distribution. Air-insulated bus ducts are a common type, utilizing air as the primary insulation medium between the conductors and the enclosure.

Construction and Components

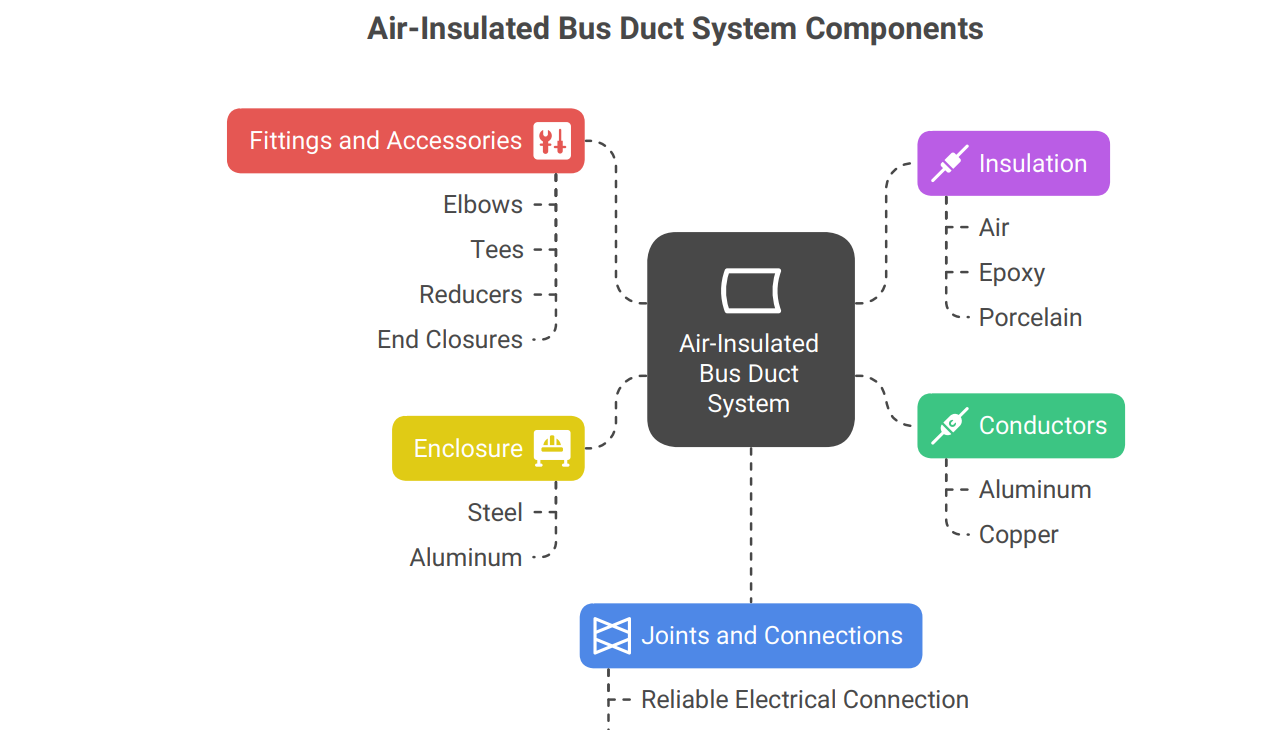

An air-insulated bus duct system typically consists of the following key components:

• Conductors: These are the current-carrying elements, typically made of aluminum or copper. The choice of material depends on factors such as current-carrying capacity, cost, and weight.

• Insulation: Air serves as the primary insulation between the conductors and the enclosure. Insulators, typically made of epoxy or porcelain, are used to support and position the conductors within the enclosure, maintaining proper spacing and preventing short circuits.

• Enclosure: The enclosure provides mechanical protection for the conductors and insulation, as well as electrical shielding. It is typically made of steel or aluminum and is designed to meet specific environmental requirements, such as protection against dust, water, and corrosion.

• Joints and Connections: These are used to connect sections of the bus duct together and to connect the bus duct to other electrical equipment, such as transformers, switchgear, and panelboards. Joints are designed to provide a reliable electrical connection and to maintain the integrity of the insulation system.

• Fittings and Accessories: A variety of fittings and accessories are available to accommodate different installation requirements, such as elbows, tees, reducers, and end closures.

Aluminum vs. Copper Conductors

The choice between aluminum and copper conductors is a critical decision in the design of an air-insulated bus duct system. Each material has its own advantages and disadvantages:

Aluminum:

Advantages:

• Lower Cost: Aluminum is generally less expensive than copper, making it a more economical choice for large installations.

• Lighter Weight: Aluminum is significantly lighter than copper, which can reduce installation costs and structural support requirements.

• Good Conductivity: While not as conductive as copper, aluminum still offers good conductivity for most applications.

Disadvantages:

• Lower Conductivity: Aluminum has lower conductivity than copper, requiring larger conductor sizes for the same current-carrying capacity.

• Higher Coefficient of Expansion: Aluminum has a higher coefficient of thermal expansion than copper, which can lead to issues with joint integrity if not properly addressed.

• Corrosion: Aluminum is susceptible to galvanic corrosion when in contact with dissimilar metals in the presence of moisture.

Copper:

Advantages:

• Higher Conductivity: Copper has higher conductivity than aluminum, allowing for smaller conductor sizes and reduced voltage drop.

• Lower Coefficient of Expansion: Copper has a lower coefficient of thermal expansion than aluminum, reducing the risk of joint problems.

• Corrosion Resistance: Copper is more resistant to corrosion than aluminum.

Disadvantages:

• Higher Cost: Copper is more expensive than aluminum, increasing the overall cost of the system.

• Heavier Weight: Copper is significantly heavier than aluminum, which can increase installation costs and structural support requirements.

Advantages of Air-Insulated Bus Duct Systems

Air-insulated bus duct systems offer several advantages over traditional cabling methods:

• Compact Design: Bus duct systems are more compact than cable systems, requiring less space for installation.

• Flexibility: Bus duct systems can be easily reconfigured or expanded to meet changing power distribution needs.

• Reliability: Bus duct systems are designed for high reliability and long life, with minimal maintenance requirements.

• Safety: Bus duct systems are enclosed and grounded, providing a high level of safety for personnel and equipment.

• Lower Installation Costs: Although the initial material cost might be higher, the reduced installation time and labor can result in lower overall costs.

• Improved Aesthetics: Bus duct systems offer a cleaner and more organized appearance compared to cable trays.

Disadvantages of Air-Insulated Bus Duct Systems

Despite their advantages, air-insulated bus duct systems also have some disadvantages:

• Higher Initial Cost: The initial cost of a bus duct system can be higher than that of a cable system, especially when using copper conductors.

• Limited Flexibility in Routing: Bus duct systems are less flexible than cable systems in terms of routing, requiring more careful planning and design.

• Potential for Condensation: In humid environments, condensation can form inside the enclosure, potentially leading to corrosion or insulation breakdown.

• Susceptibility to Dust and Contaminants: Air-insulated systems can be susceptible to dust and contaminants, which can reduce the insulation resistance and increase the risk of flashover.

Applications

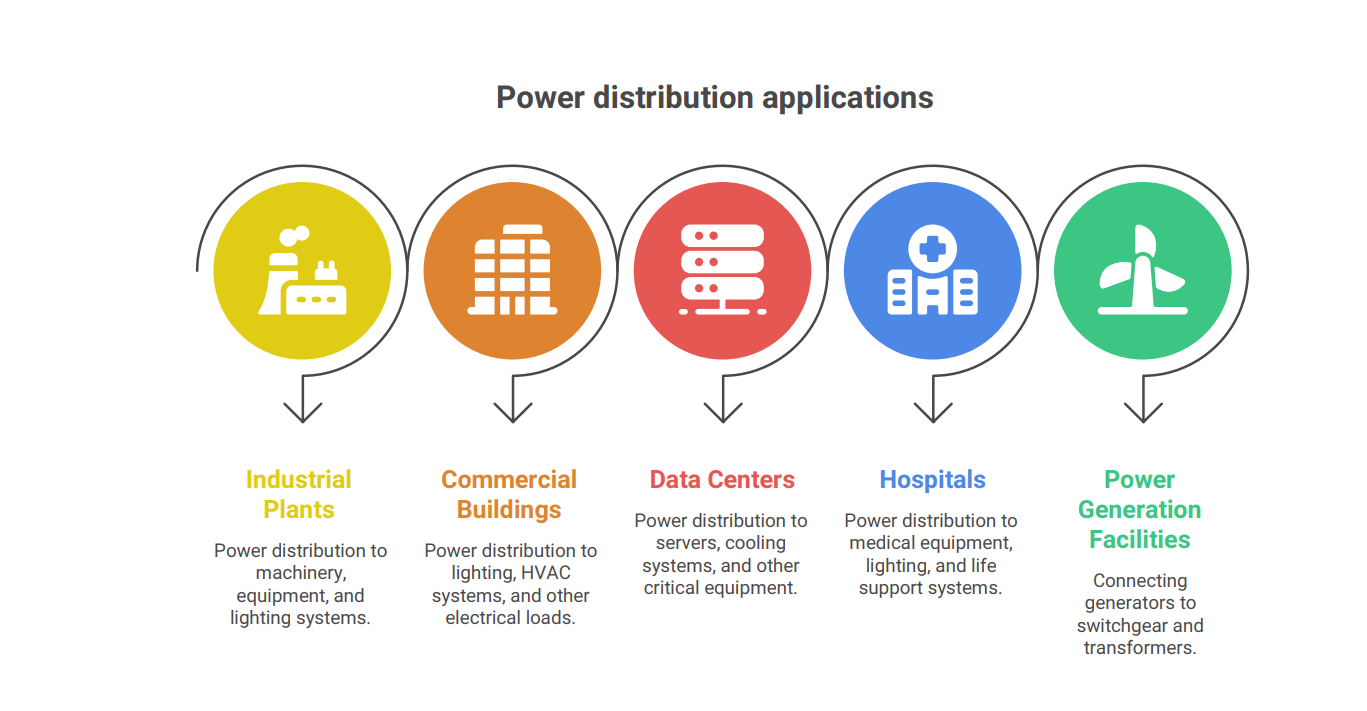

Air-insulated bus duct systems are used in a wide range of applications, including:

• Industrial Plants: Power distribution to machinery, equipment, and lighting systems.

• Commercial Buildings: Power distribution to lighting, HVAC systems, and other electrical loads.

• Data Centers: Power distribution to servers, cooling systems, and other critical equipment.

• Hospitals: Power distribution to medical equipment, lighting, and life support systems.

• Power Generation Facilities: Connecting generators to switchgear and transformers.

Selection and Installation Considerations

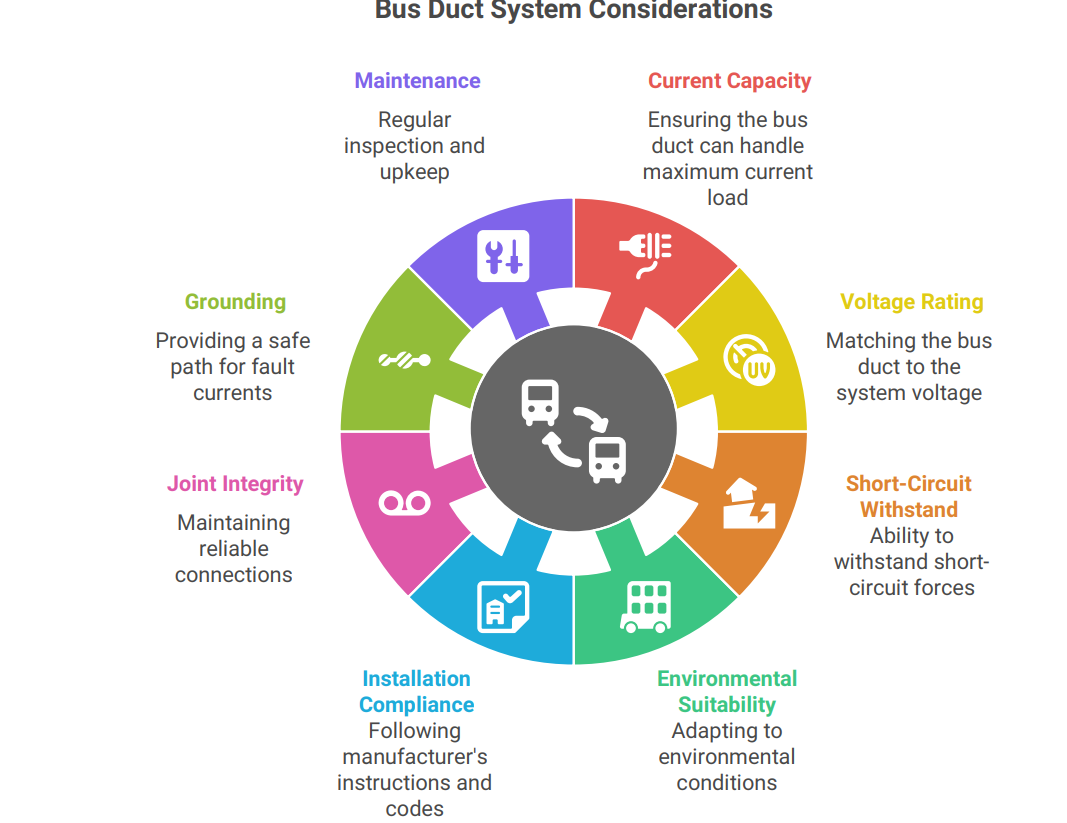

When selecting and installing an air-insulated bus duct system, the following factors should be considered:

• Current-Carrying Capacity: The bus duct must be sized to handle the maximum expected current load.

• Voltage Rating: The bus duct must be rated for the system voltage.

• Short-Circuit Withstand Rating: The bus duct must be able to withstand the forces and thermal effects of a short-circuit fault.

• Environmental Conditions: The bus duct must be suitable for the environmental conditions in which it will be installed, such as temperature, humidity, and exposure to dust or corrosive substances.

• Installation Requirements: The bus duct must be installed in accordance with the manufacturer's instructions and applicable codes and standards.

• Joint Integrity: Proper installation and maintenance of joints are critical to ensure the reliability of the system.

• Grounding: The bus duct enclosure must be properly grounded to provide a safe path for fault currents.

• Maintenance: Regular inspection and maintenance are necessary to ensure the long-term reliability of the system.

Conclusion

Air-insulated aluminum/copper bus duct systems offer a reliable, efficient, and flexible solution for power distribution in a variety of applications. By carefully considering the factors outlined in this document, engineers, designers, and facility managers can select and install a bus duct system that meets their specific needs and provides years of trouble-free operation. The choice between aluminum and copper conductors depends on a balance of cost, performance, and environmental considerations. Proper installation and maintenance are essential to ensure the long-term reliability and safety of the system.