Introduction to Feeder Pillars

Feeder pillars are freestanding enclosures that house electrical switchgear, protection devices, and distribution components. They serve as a termination and distribution point for incoming power cables and provide outgoing circuits to various loads. These pillars are designed to be robust and weatherproof, suitable for both indoor and outdoor environments. They play a vital role in distributing electricity safely and efficiently in residential, commercial, and industrial settings.

Purpose of Feeder Pillars

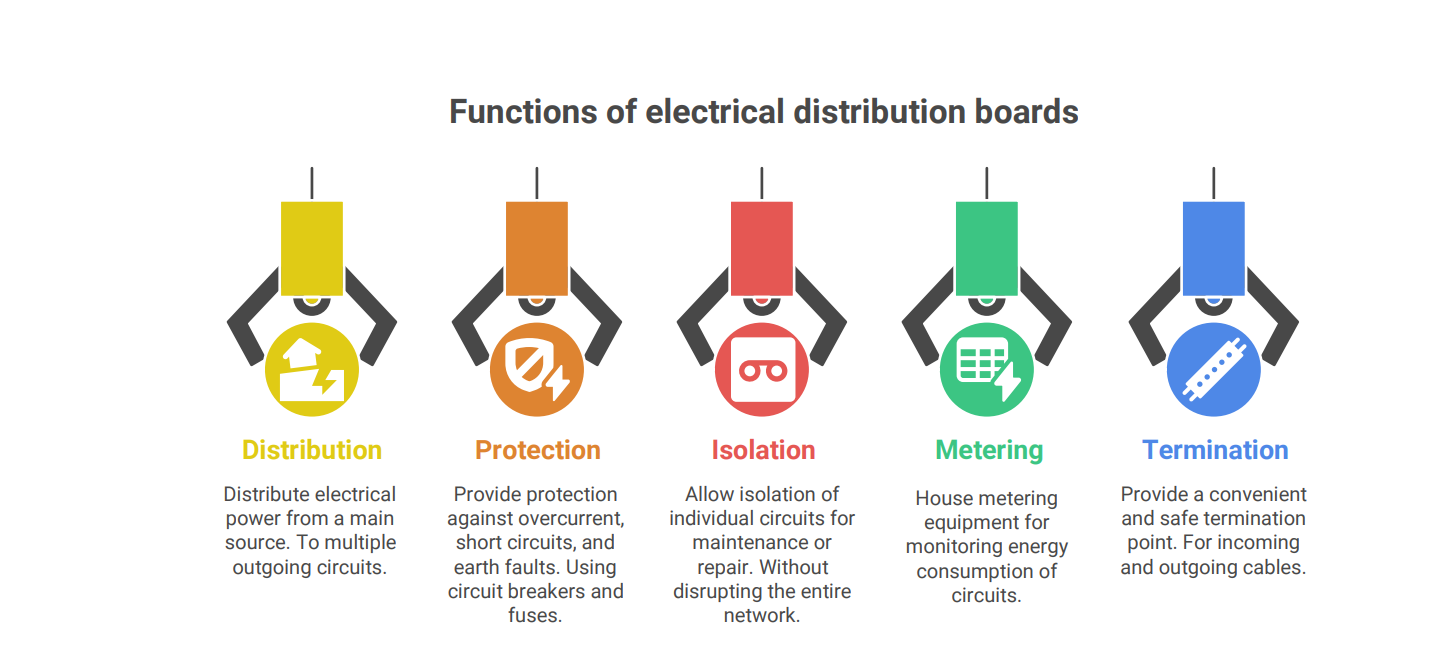

The primary purposes of feeder pillars are:

• Distribution: To distribute electrical power from a main source to multiple outgoing circuits.

• Protection: To provide protection against overcurrent, short circuits, and earth faults using circuit breakers, fuses, and other protective devices.

• Isolation: To allow for isolation of individual circuits for maintenance or repair without disrupting the entire network.

• Metering: To house metering equipment for monitoring energy consumption.

• Termination: To provide a convenient and safe termination point for incoming and outgoing cables.

Construction of Feeder Pillars

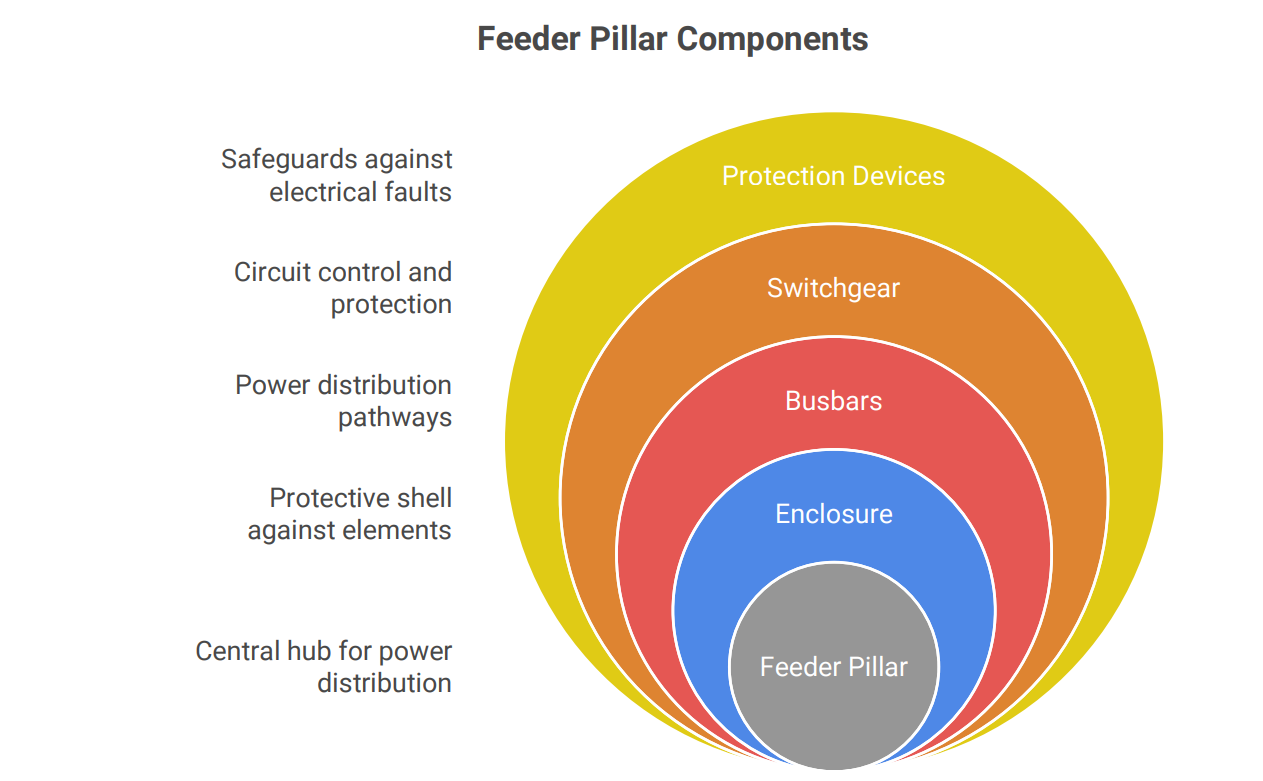

Feeder pillars typically consist of the following components:

• Enclosure: The enclosure is usually made of steel, stainless steel, or fiberglass. Itprovides mechanical protection for the internal components and protects against environmental factors such as rain, dust, and corrosion. Outdoor enclosures aredesigned to be weatherproof and may include features like gaskets and drainage systems.

• Busbars: Busbars are conductive bars that distribute power within the pillar. They are typically made of copper or aluminum and are sized to handle the rated current.

• Switchgear: Switchgear includes circuit breakers, fuses, switches, and other devices used to control and protect the outgoing circuits.

• Protection Devices: Protection devices such as miniature circuit breakers (MCBs), molded case circuit breakers (MCCBs), residual current devices (RCDs), and surge protection devices (SPDs) are installed to protect against electrical faults.

• Metering Equipment: Metering equipment, such as energy meters and current transformers (CTs), may be included to monitor energy consumption.

• Cable Terminations: Cable terminations provide a secure and reliable connection point for incoming and outgoing cables.

• Earthing System: An earthing system is essential for safety and provides a path for fault currents to flow to earth

Types of Feeder Pillars

Feeder pillars can be classified based on several factors, including:

• Location: Indoor or outdoor

• Voltage Level: Low voltage (LV)

• Construction Material: Steel, stainless steel, fiberglass

• Functionality: Distribution, metering, protection

Indoor Feeder Pillars

Indoor feeder pillars are designed for use in protected environments such as substations, switch rooms, and industrial facilities. They are typically smaller and less robust than outdoor pillars, as they do not need to withstand harsh weather conditions.

Outdoor Feeder Pillars

Outdoor feeder pillars are designed to withstand exposure to the elements, including rain, snow, wind, and sunlight. They are typically constructed from weatherproof materials such as stainless steel or fiberglass and may include features like gaskets, drainage systems, and UV protection.

Applications of Feeder Pillars

Feeder pillars are used in a wide range of applications, including:

• Residential Developments: Distributing power to individual homes or apartments.

• Commercial Buildings: Providing power to offices, shops, and other commercial establishments.

• Industrial Facilities: Distributing power to machinery, equipment, and lighting systems.

• Infrastructure Projects: Supplying power to street lighting, traffic signals, and other infrastructure components.

• Renewable Energy Systems: Connecting solar panels or wind turbines to the grid.

Key Considerations for Installation

When installing feeder pillars, several factors must be considered to ensure safe and reliable operation:

• Location: The location of the feeder pillar should be easily accessible for maintenance and inspection. It should also be protected from physical damage and environmental hazards.

• Grounding: Proper grounding is essential for safety and should be in accordance with local regulations and standards.

• Cable Management: Cables should be properly supported and protected to prevent damage and ensure reliable connections.

• Ventilation: Adequate ventilation is necessary to prevent overheating of the internal components.

• Security: The feeder pillar should be secured to prevent unauthorized access and tampering.

• Compliance: The installation should comply with all relevant electrical codes and standards.

Maintenance of Feeder Pillars

Regular maintenance is essential to ensure the continued safe and reliable operation of feeder pillars. Maintenance activities may include:

• Visual Inspection: Checking for signs of damage, corrosion, or overheating.

• Cleaning: Removing dust, dirt, and debris from the enclosure and internal components.

• Testing: Testing the operation of circuit breakers, fuses, and other protective devices.

• Tightening Connections: Ensuring that all electrical connections are tight and secure.

• Insulation Testing: Testing the insulation resistance of cables and components.

• Thermographic Surveys: Using thermal imaging to identify hotspots and potential problems.

Standards and Regulations

Feeder pillars must comply with relevant electrical codes and standards, such as:

• IS 8623/IEC 60439/IEC 61439: Low-voltage switchgear and controlgear assemblies

Conclusion

Low voltage feeder pillars are critical components in electrical distribution networks, providing a safe and efficient means of distributing power to various loads. Understanding their purpose, construction, types, applications, and key considerations for installation and maintenance is essential for ensuring reliable and safe power supply. By following best practices and adhering to relevant standards and regulations, engineers and technicians can ensure that feeder pillars operate effectively and contribute to the overall reliability of the

electrical system